Model A & B

Ford Garage

TREMEC T170FT RTS Four-Speed TOD

3+1 Overdrive Transmission Conversion

This (lengthy) page is best viewed on a Desktop or Laptop computer

The Ford F-150 RTS top shift overdrive transmission was made in Mexico for Ford by TREMEC (Transmisiones y Equipos Mecánicos), and it is known variously as a T170FT RTS / TOD / 3+1.

The RTS/TOD is a four-speed including overdrive, and was produced in three different overdrive ratios for use in 1984-87 Ford full-size light-duty 2WD and 4WD F-150 pickup trucks and Broncos.

With its cover-mounted cane shifter, the T170FT RTS / TOD / 3+1 transmission has been a popular choice for Model A and early V8 Ford overdrive transmission conversions, and a number of people have made complete kits available to do the transmission swap and conversion.

The practical and aesthetic benefit of the RTS 3+1 TOD overdrive transmission in an early Ford conversion is that it places the single shift lever in nearly the stock location on the floor, maintains a torque tube enclosed drive, and does so without any frame or brake modifications or complicated open driveline fabrication!

The relative simplicity of the RTS 3+1 TOD conversion is something that cannot be said of five-speed Borg Warner/TREMEC T5 overdrive transmission conversions. Also, the RTS 3+1 TOD does not add an additional floor shift lever, unlike the popular Mitchell torque tube overdrive unit.

fordgarage.com

fordgarage.com

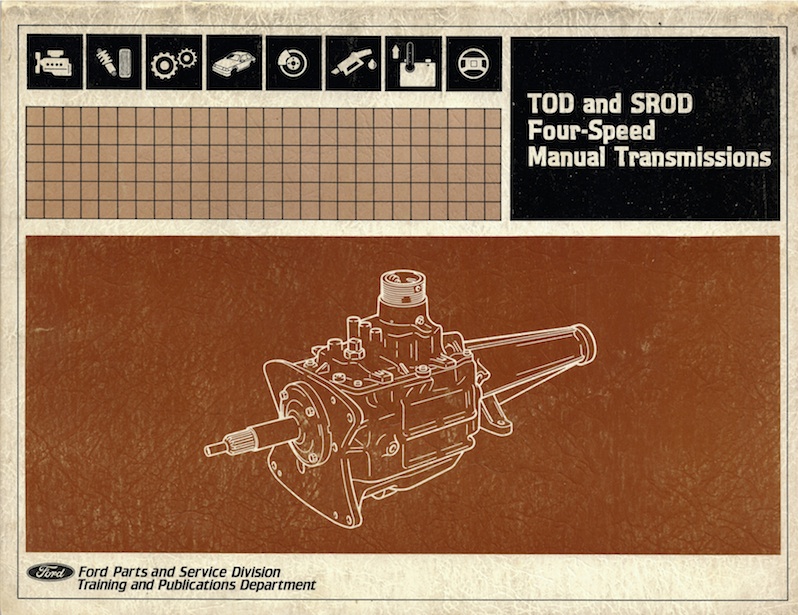

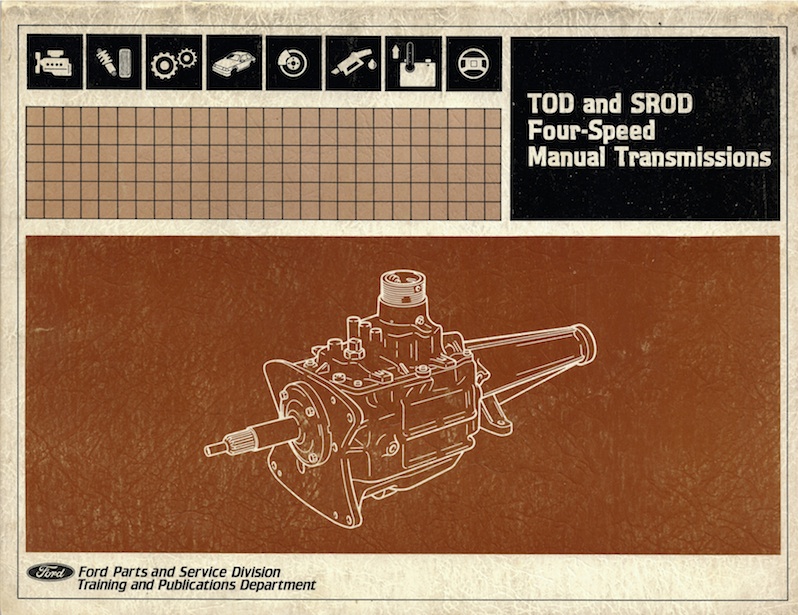

Procure this book!

Eighty-two pages of detailed official 1980-87 Ford disassembly and reassembly photos, diagrams, description, and instructions specifically for the T170FT TOD/RTS and SROD/RUG aluminum 3+1 Truck transmissions. This is the most complete technical service information ever published for the RTS transmission.

TOD & SROD Service Manual PDF (slow download)

The similar

1977 Ford Chassis Service Highlights publication covers the earlier 1977-87 T170F iron case SMOD/RUG-BP 3+1 Car (and follow-on truck

& van) transmissions. The

1979 Ford Chassis Service Highlights publication covers the 1979-83 T170FS aluminum case SROD/RUG 3+1 Car (and follow-on truck) transmissions.

This Ford Garage web page is the single most comprehensive, complete, and correct source of technical information to be found on the internet for the TREMEC RTS 3+1 TOD transmission, and also for the broader family of T170 overdrive transmission variants. Technical specifications were collected from original Ford publications, as well as from era aftermarket gear supplier catalogs.

Additional info comes from my personal ownership and parts experience with each variant of the T170 truck and van versions, including the aluminum RTS TOD in all three ratios in both 2WD an 4WD, cast iron RUG SMODs in two ratios, and aluminum RUG SRODs in three ratios.

I have also been inspired, educated, and assisted by many fellow hobbyists, especially Al Berry, Tom Aceves, and Carl Godsoe, who have shared their knowledge and enthusiasm for the T170 on message boards such as the F150 forum, the FTE forum, the Ford Barn forum, the HAMB, and others.

Please contact me by clicking my name at the bottom of this page if you have questions, additional info, or potential corrections or clarifications to contribute. Thank you!

Vince Falter

TREMEC T170 3+1 Gear Set Ratio and Drivability Summary:

Assumes 3.78 rear axle and standard tires.

Blue-shaded attributes are equivalent to the stock Model A baseline.

Green-shaded transmissions, ratios, and attributes are preferred for improved drivability compared to a stock Model A.

Yellow-shaded attributes are not optimal.

Violet/Red-shaded are the least desirable.

Transmission

(driveability) |

1st |

2nd |

3rd |

4th |

% OD |

Rev |

Comment |

Stock Model A

1928-31

(baseline reference) |

3.12 |

1.85 |

1 |

~ |

~ |

3.75 |

Stock Model A 1st and 2nd gear ratios are actually quite poor.

Stock Model A 2nd to 3rd gear gap is actually quite large.

Rear axle ratios and tire size changes cannot overcome these facts. |

Stock Model B

1932-34

(better than Model A) |

2.82 |

1.60 |

1 |

~ |

~ |

3.38 |

The overall drivability of the Model B transmission when coupled to a 27% Laycock torque tube overdrive is better than the RUG "Goldilocks" gear set in an RTS transmission case. |

RUG 'Goldilocks'

Gear Set 'A'

(best overall in RTS) |

3.01 |

1.78 |

1 |

0.7874 |

27.0% |

3.01 |

Best overall Gear Set for use in an early Ford RTS conversion.

Taller 1st and 2nd gear ratios are more favorable compared to a stock Model A, or RTS 'B' and 'D' ratios.

Improved 2-3 shift gap compared to a stock Model A, or RTS 'B' and 'D' ratios.

More favorable 4th gear (overdrive) ratio than RTS 'C' and 'D' ratios. |

RTS 'C ratio'

(better in town

than 'B' ratio) |

3.01 |

1.78 |

1 |

0.7247 |

37.9% |

3.01 |

Suitable for flatland, or lighter cars with stronger engines.

Taller 1st and 2nd gear ratios are more favorable compared to a stock Model A, or RTS 'B' and 'D' ratios.

Improved 2-3 shift gap compared to a stock Model A, or RTS 'B' and 'D' ratios.

More favorable 4th gear (overdrive) ratio than RTS 'D' ratio. |

RTS 'B ratio'

(better on highway

than 'C' ratio) |

3.25 |

1.92 |

1 |

0.7837 |

27.6% |

3.25 |

Suitable for hill country, or heavier underpowered cars.

'Worse' 2nd to 3rd gear gap compared to a stock Model A, or RTS 'C' or RUG "Goldilocks" ratios.

More favorable 4th gear (overdrive) ratio than RTS 'C' and 'D' ratios. |

RTS 'D ratio'

(useless) |

3.25 |

1.92 |

1 |

0.7087 |

41.1% |

3.25 |

NFG for vintage Ford conversions, except as a parts donor.

Can be converted to 'B' ratio by swapping proper Cluster and OD Gears. |

|

1st |

2nd |

3rd |

4th |

% OD |

Rev |

|

| RTS Ratio Codes and Application |

Ford Tag Numbers |

41.1% RTS 'D ratio'

AB 2WD

AC 2WD

AG 4WD

BM 4WD

BS 2WD

BT 2WD

BY 4WD

27.6% RTS 'B ratio'

AD 2WD

AE 2WD

AJ 4WD

BP 4WD

BU 2WD

BV 2WD

BZ 4WD

CA 4WD

37.9% RTS 'C ratio'

AA 2WD

AF 2WD

AH 4WD

AK 2WD

BN 4WD

BR 2WD

BW 4WD |

E4TR BA

E4TR CA

E4TR GA

E6TR EA

E6TR JA

E6TR KA

E6TR PA

E4TR DA

E4TR EA

E4TR JA

E6TR GA

E6TR LA

E6TR MA

E6TR RA

E7TR AA

E4TR AA

E4TR FA

E4TR HA

E4TR NA

E6TR FA

E6TR HA

E6TR NA |

Ford-TREMEC T170 3+1 Family Variants

The Ford-TREMEC T170 manual transmission family includes three types/variants of four-speed toploaders having the internal 'third' gear position configured as the top/overdrive gear ('fourth' gear to the driver).

The family of T170 variants are also known as '3+1 Overdrives'.

The major visual differences between the three T170 types/variants are in the style of gear selection, and in the case materials used.

-

The 1977-87 cast iron case T170F RUG 3+1 (aka SMOD) side-mounted external shifter variants were used in some 1977-78 Ford cars (cast iron RUG-BP), 1978-79 2WD F-150 pickup trucks (cast iron RUG-CB, CD), and in 1978-87 E-150 Econoline vans (cast iron RUG-CL, FP, FZ, GA). These are externally side-lever shifted, and have a stamped steel 10-bolt top cover.

The T170F RUG 3+1 SMOD has a gate shifter lever and linkages (Hurst style) mounted externally on the cast iron tail shaft housing. None of the cast iron RUGs have a tail shaft housing-mounted turret shifter (aluminum RUG 3+1 SROD style), nor a case-mounted top shifter cover with cane shifter (aluminum RTS 3+1 TOD style).

The T170F RUG 3+1 SMOD has exposed steel links and levers, and they are subject to corrosion, ice and mud buildup, and jamming from branches and road debris, etc.

All cast iron T170F RUG 3+1 SMODs tagged RUG-CB/CD or RUG-CL/FP/FZ/GA are pickup truck and van transmissions, and they share many internal gears and parts with the RTS 3+1 TOD, and are a useful parts donor resource for an RTS 3+1 TOD (re)build.

Note: The cast iron T170F RUG 3+1 SMOD tagged RUG-BP is specifically a unique car transmission and has virtually no internal parts which are usable or interchangeable in an RTS 3+1 TOD, despite the RUG-BP parts being visually quite similar to truck and van RUG and RTS parts.

As an additional note, all cast iron T170F RUG 3+1 SMOD transmissions are very similar in design and appearance to the earlier (non-overdrive) Ford 3.25" center distance HEH & RUG four-speed toploader performance transmissions of the 1960s-70s, and are sometimes visually mistaken for them.

-

The aluminum case T170FS RUG 3+1 SROD design variant was used in some 1979-83 Ford cars as well as in 1980-83 F-150 2WD & 4WD pickup trucks. The T170FS is a Single Rail Over Drive, having an enclosed rail tube and a remote-mounted turret shifter housing on the aluminum tail shaft extension.

This enclosed shifting arrangement on the T170FS RUG 3+1 SROD variant offers improved environmental protection for the shift components.

The SROD does not have a case-mounted RTS 3+1 TOD-style top shifter, nor an external SMOD style case-mounted gate shifter linkage. However, it does have a stamped steel 10-bolt top cover the same as the earlier cast iron RUG 3+1 SMOD.

Many of the internal gears in the 1980-83 Truck (but not Car) aluminum T170FS RUG 3+1 SROD variants are usable and interchangeable in a T170FT RTS 3+1 TOD (re)build.

-

The 1984-87 aluminum case T170FT RTS 3+1 TOD design variant is a toploader overdrive transmission and was produced exclusively for use in 1984-87 F-150 pickups and Broncos, both 2WD and 4WD.

The T170FT RTS 3+1 TOD variant has a cane shifter tower/cover arrangement mounted on top of the gear case, specifically to suit trucks, not vans or cars.

Only the T170FT RTS 3+1 TOD has a case-mounted aluminum top shifter cover with a cane shifter.

The T170FT RTS 3+1 TOD variant is the primary subject of this web page, and is the sought-after transmission for early Ford overdrive conversions.

Ford-TREMEC T170 3+1 Family Geartrain Arrangement

In the T170 family of transmissions, the overdrive (highest gear) is actually located in the internal 'third' gear position, and power is NOT directly transferred in-line through the input to the output shaft when in overdrive gear (highest gear). This is unlike a conventional 'fourth' gear (high gear) in a non-overdrive Ford four-speed toploader transmission.

Instead, the power in the T170 during overdrive operation is routed through the input main drive gear, into the cluster gear, back into the overdrive gear teeth on the main/output shaft, and then on to the universal joint. The countershaft, input, and overdrive gears, input and main shafts, and all bearings as well as the case itself are always under radial separation load and stress during overdrive operation.

The continuous offset loads on all the bearings, and on the main, cluster, and overdrive gears during overdrive operation is one reason why these 3+1 transmissions originally developed a somewhat poor reputation for robustness when abused, compared to the robustness of the high gear loading in a planetary overdrive or in a conventional non-overdrive transmission.

Regarding Durability Reputation:

The reputation of questionable durability of the 3+1 was primarily caused by the many abusive F-150 pickup truck and van owners who were often towing heavy trailer loads in 4th (overdrive), instead of in 3rd (direct drive) gear as recommended by Ford.

In spite of this era reputation, the aluminum-case T170FT RTS 3+1 TOD truck transmission is more than robust enough in overdrive for usage in a Model A or Early V8 Ford.

1984-87 TREMEC T170FT RTS 3+1 TOD Description

Ford Parts and Service Division

Ford Service Manual Description:

The top shift overdrive (TOD) is a four-speed manual transmission with fourth gear as an overdrive.

It is fully synchronized. All forward gears are helical-type and are in constant mesh. The forward gear changes are accomplished with synchronizer sleeves.

Reverse is provided through a reverse idler sliding gear which slides on a reverse idler gear. The reverse idler gear is in constant mesh with the countershaft gear. In reverse the spur-type gear on the reverse idler sliding gear meshes with the gear on the 1-2 synchronizer hub.

The top mounted shifter operates shift rails in the transmission cover assembly. The first-second fork and the reverse fork are attached directly to these rails.

The third and overdrive shift fork is attached to a shift rail which is mounted in the transmission case.

Third and overdrive are shifted by means of a shift pawl mounted on a rail in the transmission cover, contacting an overdrive shift control link in the transmission. This shift control link contacts the shift fork in the transmission.

A shift interlock system located in the transmission cover prevents the engagement of more than one gear at a time.

The transmission case, cover, and extension housing are aluminum. The mating surfaces of these components are sealed with Anaerobic Sealer (Gasket Eliminator).

| OEM Application: |

1984 - 1987 Ford F-150

both 2WD and 4WD |

| Ford Type: |

Four-Speed Manual TOD

Topshift Over Drive |

| Manufacturer: |

TREMEC |

| TREMEC Type: |

T170FT RTS

Remote Tower/Top Shift |

| Case Material: |

Aluminum alloy |

| Fully Synchronized: |

All forward gears

are helical type

in constant mesh |

| Lubricant: |

3.5 US Pints

1.7 Liters

SAE 80W

D8DZ-19C547-A

(ESP-M2C83-C)

Driven 80W-90 GL4

Sta-Lube SAE 90 GL4

or equivalent

Do not use GL5 !

(brass synchro rings) |

| Notes: |

3 OD ratios produced |

| Case has no drain plug |

No gaskets are used;

Anaerobic sealer only |

| TOD = Topshift Over Drive |

| RTS = Remote Top Shift |

1984-87 TREMEC T170FT RTS 3+1 TOD Identification

There is both a Ford casting part number and a TREMEC casting part number cast into the LH side of the aluminum RTS case. The first (1984) style case is marked RF-E4TR-7006-AA and C-2604877, and the second (1985-87) style case is marked RF-E5TR-7006-AA and C-2605524.

You may also find a similar 3+1 OD four-speed 'RTS style' top shift aluminum case transmission, with a Ford input shaft and an 'RTS style' top shifter (not Jeep), but without any Ford casting numbers or logo, and having only a TREMEC case casting number C-2605275.

These 'RTS clones' were made by TREMEC, but are not marked 'RTS' on the steel tag. I believe they may have been complete replacement F-150 transmissions supplied/marketed by TREMEC directly to aftermarket/independent transmission shops. Anybody know differently?

1985 F-150 2WD Regular Cab Pickup

1987 F-150 2WD Regular Cab, Six Cylinder with TREMEC T170FT RTS transmission

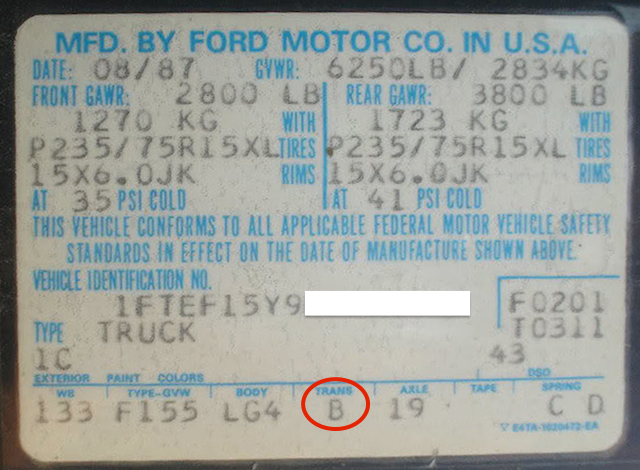

When still in a vehicle, the TREMEC T170 3+1 transmission can also be identified by the Ford transmission ID code 'B' (= TREMEC 3+1 OD) printed at the bottom center of the VIN/GVWR/Tire Information label (applied inside the drivers door opening) of a Ford F-150 pickup truck or Bronco, as shown above.

Overdrive Ratio Identification

The information published in the official 1983

Ford Parts and Service Division TOD and SROD Service Manual identifies three different gear ratio configurations offered in the TREMEC

T170FT RTS TOD and the

T170FS RUG SROD series F-150 truck transmissions, and they are specified as 'B ratio', 'C ratio', and 'D ratio'.

'B' ratio = 27.6% overdrive (4th=0.7837) (5.0L 302 V8, also some 4.9L 300 I6)

'C' ratio = 37.9% overdrive (4th=0.7247) (5.8L 351 V8, also some 4.9L 300 I6)

'D' ratio = 41.1% overdrive (4th=0.7087) (4.9L 300 I6)

These Ford ratio letters are utilized in Column 1 in the

Transmission Specifications table below to organize the part gearing information of the three different RTS overdrive configurations.

Note:There is also a fourth (quite rare) T170 3+1 gear set configuration I refer to as the

"Goldilocks". It was only available in the earlier cast iron

T170F RUG SMOD, and was used only in the 1978-79 Econoline van with the 5.8L 351 V8.

All other truck and van cast iron RUG SMODs have a 'B ratio' gear set (with its inherently poor 1st and 2nd gear ratios, and large 2nd to 3rd gear gap. (like a stock Model A)

The "Goldilocks", however, has a favorable 27.0% 4th gear OD ratio, but also with taller 1st and 2nd gear ratios, and with a reduced 2-3 gear gap.

This results in much improved overall drivability compared to all other RUG and RTS T170 gear sets (ratios 'B', 'C', and 'D') when used in an RTS case in a Model A or with an early flathead V8 Ford.

If you are fortunate enough to find one of these "Goldilocks" ratio RUG Econoline gear sets, they can be directly retrofit into the aluminum case of the 1984-87 T170FT RTS TOD.

I consider this "Goldilocks" to be the most desirable gear set for all ratios from 1st through 4th gear for overall drivability in a vintage Ford conversion.

fordgarage.com

fordgarage.com

The 4th gear overdrive ratio of a T170 transmission can be identified by a steel tag which is riveted to the front RH side of the case. This is useful when evaluating a loose transmission at a junk yard or swap meet.

The first three characters on the T170FT RTS tag will be 'RTS', and are immediately followed by a two-character alpha code as shown in the pic above, and in Column 1 in the table below.

The two-character alpha code identifies the overdrive ratio, as originally built by TREMEC.

Other than identifying the specific transmission OD ratio, the RTS two-character alpha code is unimportant in adapting the T170FT to the Model A or early V8 Ford.

Beyond identifying the OD ratio, the two-character alpha code following the 'RTS' identifies the original transmission assembly as being for a 2WD or 4WD, and identifies which speedometer drive gear it was originally equipped with (function of tire size and rear axle ratio combinations).

The various other codes stamped on the TREMEC tag identify the production date, the Ford service designation number, and the TREMEC daily unit serial number.

1984-87 TREMEC T170FT Aluminum RTS 3+1 (TOD) Specifications

The Transmission Specifications table below shows the Ford and aftermarket part numbers and tooth counts of the various gears in each RTS transmission configuration.

Peach-shaded cells indicate gears which are still generally available new in the aftermarket.

1984-87 F-150 Truck Aluminum RTS Transmissions

RTS transmissions used as the basis for Model A and early V8 Ford overdrive conversions |

|---|

T170FT RTS 3+1 (TOD)

Aluminum Top Shifter

Transmission Codes |

Ford, TREMEC, and Aftermarket Part Numbers and Tooth Counts |

TREMEC Codes

T170FT

Steel ID Tag

Alpha Codes |

% OD

Gear

Ratios |

Countershaft

Cluster Gear

(Input-4-2-1)

(3 distinct) |

Input Gear

1-1/16" Dia

10 spline

(2 distinct) |

3rd

Gear

Sleeve |

4th OD

Gear

(2 distinct) |

2nd

Gear

(1 common) |

1st

Gear

(1 common) |

'C ratio'

RTS-

AA, AF, AH,

AK, BN, BR,

BW

1984-87 F-150/Bronco

4.9L 300 I6

5.8L 351 V8 |

'C' ratio

37.9%

1st=3.0061

2nd=1.7767

3rd=1.0000

4th=0.7247 |

31-35-23-15

E0TZ-7113-B

2603243

T170-8J |

22T

E0TZ-7017-C

2604485

T170-16P

8-7/8" long

2G equal

(interchanges

w/ RUG 3+1) |

3rd

Direct |

18T

E0TZ-7B340-B

2604242

T170-11J

1G forward

(interchanges

w/ RUG 3+1) |

29T

E0TZ-7102-A

(2604232)

2605214

T170-21F

0G

3-53/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

2G central

4-36/64"

diameter |

'B ratio'

RTS-

AD, AE, AJ,

BP, BU, BV,

BZ, CA

1984-87 F-150/Bronco

4.9L 300 I6

5.0L 302 V8 |

'B' ratio

27.6%

1st=3.2508

2nd=1.9213

3rd=1.0000

4th=0.7837 |

32-35-23-15

D8UZ-7113-A

2603740

T170-8C

1G central 15? |

21T

E0TZ-7017-B

2604484

T170-16N

8-7/8" long

(interchanges

w/ RUG 3+1) |

3rd

Direct |

18T

E0TZ-7B340-B

2604242

T170-11J

(interchanges

w/ RUG 3+1) |

29T

E0TZ-7102-A

(2604232)

2605214

T170-21F

3-53/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

'D ratio'

RTS-

AB, AC, AG,

BM, BS, BT,

BY

1984-87 F-150/Bronco

4.9L 300 I6

good for case,

shifter top,

bearing retainer,

input gear/shaft,

1 & 2 gears,

reverse gears,

synchro hubs,

output shaft

(can be converted to

RTS 'B ratio' using

27.6% RUG 3+1

cluster and OD gears) |

'D' ratio

41.1%

1st=3.2508

2nd=1.9213

3rd=1.0000

4th=0.7087 |

32-43-23-15

E0TZ-7113-A

2604234

T170-8H

(convert RTS 'D'

to 'B' ratio using

RUG 3+1

T170-8C gear) |

21T

E0TZ-7017-B

2604484

T170-16N

8-7/8" long

(interchanges

w/ RUG 3+1) |

3rd

Direct |

20T

E0TZ-7B340-A

2605212

T170-11H

1G central

2-21/64"

diameter

(convert RTS 'D'

to 'B' ratio using

RUG 3+1

T170-11C gear) |

29T

E0TZ-7102-A

(2604232)

2605214

T170-21F

3-53/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

RTS Codes

T170FT |

Gear

Ratios |

Countershaft

Cluster Gear |

Input

Gear |

3rd

Gear |

4th OD

Gear |

2nd

Gear |

1st

Gear |

IMO, the "Goldilocks" 3+1 transmission for a Model A or Model B is one closely resembling the combination of the 1st and 2nd gear ratios of an RTS 'C ratio' transmission shown above, combined with the 4th gear overdrive ratio of the RTS 'B ratio' transmission.

As it turns out, a "Goldilocks" T170 gear set configuration does exist, but was never originally offered in an 1984-87 F-150 RTS top shift aluminum case.

That elusive "Goldilocks" gear set used in an earlier specific cast-iron RUG can however be installed in a later RTS case!

Refer to the T170F Donor Transmission table below for the necessary earlier 1978-79 Econoline RUG 3+1 gears to be swapped into an RTS case to achieve a 27% OD "Goldilocks" configuration, having ratios of:

1st = 3.0061

2nd = 1.7767

3rd = 1.0000

4th = 0.7874

Refer to the Drivability and Suitability ~ Recommended Combinations section further down this page for an explanation of why this ratio configuration is theoretically the "best", or "Goldilocks", T170 transmission for an early Ford conversion.

I have only ever found and purchased three of these donor RUG "Goldilocks" van transmissions myself, and am aware of only four others recently built into T170 RTS "Goldilocks" vintage Ford conversions.

Parts Donor Transmissions:

1977-87 TREMEC T170F Cast Iron RUG 3+1 (SMOD) Specifications

Peach-shaded cells indicate gears which are still generally available new in the aftermarket.

1977-78 Cast Iron SMOD RUG Transmissions ~ Cars Use 209/307 Bearings

Not Recommended ~ No useful parts in car SMOD RUGs except 1st gear |

T170F RUG 3+1 (SMOD)

Iron Side Shifter

Transmission Codes |

% OD

Gear

Ratios |

Countershaft

Cluster Gear

(Input-4-2-1) |

Input Gear

1-1/16" Dia

10 spline |

3rd

Gear

Sleeve |

4th OD

Gear |

2nd

Gear |

1st

Gear |

D7DR-7006-AA

2603606 iron case*

2602885 retainer

(T160-6G)

*209/307 bearings

Orion RUG BP

Ford RUG BP

D7DR-AA

Not Recommended ~

No useful parts in car

RUG-BP except 1st gear

1977-78 Granada/Monarch

3.3L 200 I6 w/ 3.40:1

4.1L 250 I6 w/ 3.00:1

5.0L 302 V8 w/ 3.00:1 |

23.6%

1st=3.2889

2nd=1.8381

3rd=1.0000

4th=0.8094 |

37-40-26-15

D7DZ-7113-A

2603885

T170-8B |

24T

D7DZ-7017-A

2603596

T170-16E

8-7/8" long |

3rd

Direct |

21T

D7DZ-7B340-A

2603884

T170-11B

2-32/64"

diameter |

31T

D7DZ-7102-A

2603612

T170-21B

3-50/64" ?

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

1977-87 Cast Iron SMOD RUG Transmissions ~ Trucks & Vans use 308/308 Bearings

Parts Donors ~ Many useful gears in truck & van SMOD RUGs for use in an RTS case |

T170F RUG 3+1 (SMOD)

Iron Side Shifter

Transmission Codes |

% OD

Gear

Ratios |

Countershaft

Cluster Gear

(Input-4-2-1) |

Input Gear

1-1/16" Dia

10 spline |

3rd

Gear

Sleeve |

4th OD

Gear |

2nd

Gear |

1st

Gear |

D7DR-7006-AA

2603606 iron case

2603718 iron retainer

308/308 bearings

D8TR-JA

1978 F-250

4.9L 300 I6

Orion RUG CB

Ford RUG CB

D8TR-KA

1978-79 F-150

5.8L 351 V8

1979 F-250

5.8L 351 V8

Orion RUG CD

D8TR-MA

1978-79 F-150

4.9L 300 I6

5.0L 302 V8

1979 F-250

4.9L 300 I6

Orion RUG CL

Ford RUG CL

D8UR-EA

1978-86 Econoline

4.9L 300 I6

5.0L 302 V8

RUG FP

E3UR-BA

1983 Econoline

4.9L 300 I6

RUG FZ

E6UR-AA

1986 Econoline

4.9L 300 I6

RUG GA

E7UR-AA

1987 Econoline

4.9L 300 I6 |

'B' ratio

27.6%

1st=3.2508

2nd=1.9213

3rd=1.0000

4th=0.7837 |

32-35-23-15

D8UZ-7113-A

2603740

T170-8C

(use in RTS

case to convert

RTS 'D ratio'

into

RTS 'B ratio') |

21T

D8UZ-7017-A

2603804

T170-16F

8-7/8" long

2G central

(interchanges

w/ RTS) |

3rd

Direct |

18T

D8UZ-7B340-A

2603737

T170-11C

2G wide

(use in RTS

case to convert

RTS 'D ratio'

into

RTS 'B ratio')

2-29/64"

diameter |

29T

D8UZ-7102-A

2603738

T170-21C

2G wide

(iron case,

interchange

w/ RTS?)

3-53/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

0G

(interchanges

w/ RTS)

4-36/64"

diameter |

D7DR-7006-AA

2603606 iron case

2603718 iron retainer

308/308 bearings

Goldilocks Gearing

Taller 1 & 2 gears

Favorable 2-3 gap

plus 27% OD

(not originally

configured in RTS case)

1978-79 Econoline

5.8L 351 V8 |

27.0%

1st=3.0061

2nd=1.7767

3rd=1.0000

4th=0.7874 |

31-34-23-15

D8UZ-7113-B

2603745

T170-8D

1G central 34? |

22T

D8UZ-7017-B

2603806

T170-16G

8-7/8" long

1G central

(interchange

w/ RTS) |

3rd

Direct |

19T

D8UZ-7B340-B

2603744

T170-11D

1G central

3G even?

(interchange

w/ RTS)

2-37/64"

diameter |

29T

D8UZ-7102-A

2603738

T170-21C

2G wide

(iron case,

interchange

w/ RTS?)

3-53/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

0G

(interchanges

w/ RTS)

4-36/64"

diameter |

RUG Codes

T170F |

Gear

Ratios |

Countershaft

Cluster Gear |

Input

Gear |

3rd

Gear |

4th OD

Gear |

2nd

Gear |

1st

Gear |

|

Parts Donor Transmissions:

1979-83 TREMEC T170FS Aluminum RUG 3+1 (SROD) Specifications

| Peach-shaded cells indicate gears which are still generally available new in the aftermarket. |

1980-83 F-150 Truck Aluminum SROD RUG Transmissions ~ Uses 308/308 Bearings

Parts Donors ~ Many useful gears in truck SROD RUGs for use in an RTS case |

T170FS RUG 3+1 (SROD)

Aluminum Turret Shifter

Transmission Codes |

% OD

Gear

Ratios |

Countershaft

Cluster Gear

(Input-4-2-1) |

Input Gear

1-1/16" Dia

10 spline |

3rd

Gear

Sleeve |

4th OD

Gear |

2nd

Gear |

1st

Gear |

'C ratio'

RUG-

DC, DH, DL,

DP, DS, DT,

DV, DZ, EA,

EC, EE, EH,

EK, EN, ES,

EV, FK, FL,

FR

1980-83 F-150

5.8L 351 V8 |

'C' ratio

37.9%

1st=3.0061

2nd=1.7767

3rd=1.0000

4th=0.7247 |

31-35-23-15

E0TZ-7113-B

2603243

T170-8J |

22T

E0TZ-7017-C

2604485

T170-16P

8-7/8" long |

3rd

Direct |

18T

E0TZ-7B340-B

2604242

T170-11J |

29T

E0TZ-7102-A

(2604232)

2605214

T170-21F

3-53/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

'B ratio'

RUG-

EL, ET, FH,

FM, FN

1980-83 F-150

5.0L 302 V8

4.9L 300 I6 |

'B' ratio

27.6%

1st=3.2508

2nd=1.9213

3rd=1.0000

4th=0.7837 |

32-35-23-15

D8UZ-7113-A

2603740

T170-8C |

21T

E0TZ-7017-B

2604484

T170-16N

8-7/8" long |

3rd

Direct |

18T

E0TZ-7B340-B

2604242

T170-11J |

29T

E0TZ-7102-A

(2604232)

2605214

T170-21F

3-53/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

'D ratio'

RUG-

DB, DG, DN,

DR, DU, DY,

EB, ED, EF,

EG, EJ, EP,

ER, EU, EW,

FE, FJ

1980-83 F-150

4.9L 300 I6 |

'D' ratio

41.1%

1st=3.2508

2nd=1.9213

3rd=1.0000

4th=0.7087 |

32-43-23-15

E0TZ-7113-A

2604234

T170-8H |

21T

E0TZ-7017-B

2604484

T170-16N

8-7/8" long |

3rd

Direct |

20T

E0TZ-7B340-A

2605212

T170-11H

1G rearward

2-21/64" |

29T

E0TZ-7102-A

(2604232)

2605214

T170-21F

3-53/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

RUG Codes

T170FS |

Gear

Ratios |

Countershaft

Cluster Gear |

Input

Gear |

3rd

Gear |

4th OD

Gear |

2nd

Gear |

1st

Gear |

|

| Peach-shaded cells indicate gears which are still generally available new in the aftermarket. |

1979-83 Car

D9BR-7006-AB 2604194 aluminum case.

Aluminum SROD RUG Transmissions ~ Uses 209/307 Bearings

Not Recommended ~ No useful parts in car SROD RUGs except 1st gear |

T170FS RUG 3+1 (SROD)

Aluminum Turret Shifter

Transmission Codes |

% OD

Gear

Ratios |

Countershaft

Cluster Gear

(Input-4-2-1) |

Input Gear

1-1/16" Dia

10 spline |

3rd

Gear

Sleeve |

4th OD

Gear |

2nd

Gear |

1st

Gear |

1979-83 Fairmont/Zephyr

3.3L 200 I6 |

23.6%

1st=3.2889

2nd=1.8381

3rd=1.0000

4th=0.8094 |

37-40-26-15

D9BZ-7113-A

2604182

T170-8F |

24T

D9BZ-7017-A

2603827

T170-16H

9-5/8" long |

3rd

Direct |

21T

D9BZ-7B340-A

2604181

T170-11F

2-33/64"

diameter |

31T

D9BZ-7102-A

2603894

T170-21E

3-50/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

1979-83 Fairmont/Zephyr

5.0L 302 V8 |

35.6%

1st=3.0720

2nd=1.7169

3rd=1.0000

4th=0.7376 |

36-41-26-15

D9BZ-7113-B

2603927

T170-8G |

25T

D9BZ-7017-B

2603926

T170-16J

9-5/8" long |

3rd

Direct |

20T

D9BZ-7B340-B

2603924

T170-11G

2-26/64"

diameter |

31T

D9BZ-7102-A

2603894

T170-21E

3-50/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

Ford RUG CP

D9DR-DA

1979 Granada SST |

|

|

|

3rd

Direct |

|

|

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

1979-83 Granada/Monarch

4.1L 250 I6 |

23.6%

1st=3.2889

2nd=1.8381

3rd=1.0000

4th=0.8094 |

37-40-26-15

D9BZ-7113-A

2604182

T170-8F |

24T

D9DZ-7017-A

2603899

T170-16K

8-7/8" long |

3rd

Direct |

21T

D9BZ-7B340-A

2604181

T170-11F

2-33/64"

diameter |

31T

D9BZ-7102-A

2603894

T170-21E

3-50/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

1979-83 Granada/Monarch

5.0L 302 V8 |

35.6%

1st=3.0720

2nd=1.7169

3rd=1.0000

4th=0.7376 |

36-41-26-15

D9BZ-7113-B

2603927

T170-8G |

25T

D9DZ-7017-B

2603925

T170-16L

8-7/8" long |

3rd

Direct |

20T

D9BZ-7B340-B

2603924

T170-11G

2-26/64"

diameter |

31T

D9BZ-7102-A

2603894

T170-21E

3-50/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

RUG DA

1979-83 Mustang/Capri

Hydraulic clutch

4.1L 250 I6 |

23.6%

1st=3.2889

2nd=1.8381

3rd=1.0000

4th=0.8094 |

37-40-26-15

D9BZ-7113-A

2604182

T170-8F |

24T

D9ZZ-7017-A

2603898

T170-16M

11-1/16" long |

3rd

Direct |

21T

D9BZ-7B340-A

2604181

T170-11F

2-33/64"

diameter |

31T

D9BZ-7102-A

2603894

T170-21E

3-50/64"

diameter |

32T

D9BZ-7A029-B

2604300

J8132389

T170-12B

4-36/64"

diameter |

RUG EM

1979-83 Mustang/Capri

5.0L 302 V8 |

35.6%

1st=3.0720

2nd=1.7169

3rd=1.0000

4th=0.7376 |

|

20T?

209 bearing

?" long |

3rd

Direct |

|

|

|

|

Ancillary T170 Parts:

| Peach-shaded cells indicate parts which are still generally available new in the aftermarket. |

| RTS 3+1 Component Parts |

Part Numbers |

RTS Aluminum Main Case

(bored for 308/308 bearings)

Overall Case Length 10-1/8"

Case Face-to-Input Shaft Nose 6-7/16"

Case Face-to-Retainer Nose 3-21/32" |

T170-1F

E4TZ-7005-B

C-2604877

C-2605524 |

Front Bearing Retainer (T170 Truck & Van)

(for 308 bearing)

Overall Length 3-13/16”

Outside Diameter 1-7/16" (1.430 inches)

For 1-1/16" input shaft

Retainer OD 4.850" |

T170-6C

2605314 CI RTS

E4TZ-7050-A CI RTS

cast iron

w/ pry notches

uses sealer

2603718 CI RUG 3+1

D8UZ-7050-A CI RUG 3+1

cast iron

w/o pry notches

uses gasket

E0TZ-7050-A AL SROD

326724A

aluminum

uses gasket

RF-E0TR-7050-AA AL SROD

C2604224-1B |

Front Bearing Retainer (T170 1979-83 Car)

(for 209 bearing) |

WT170-6G

326724B

cast iron

w/o pry notches

uses gasket |

Main Drive Gear (input) Ball Bearing

Main Shaft (output) Ball Bearing

used with 2.73mm input spacer ring |

308L4

40mm ID x 90mm OD x

23mm Wide, w/ lock ring

KOYO 83763-1

KOYO 83763-3

Ford D8UZ-7025-A P.F.

Ford E5TZ-7025-C S.F.

KOYO NU308C3

743202-L4

308LTB

MRC 308 SZZG double shield

6308 2RSNR double seal

SKF 6308 2RS1NR double seal |

Input Shaft Ball Bearing Snap Ring

(#61 in parts illustration) |

D8UZ-7064-A |

Input Shaft (main drive gear) Oil Seal

1.125" Inside Diameter for shaft

1.624" Outside Diameter

0.250" Width |

CR/SKF 11111

CR/SKF 11123

CR/SKF 11124

D8UZ-7A283-B

E3FZ-7A011-A

National 3638

Victor Dana 45820

Victor Dana 47499 |

Input Shaft Cylindrical Roller Bearings

15 required |

C3AZ-7118-A

C417Q

BCA Federal Mogul |

Main Shaft (output)

2WD (23-11/32")

32-37-28 Splines |

T170-2K

E0TZ-7061-C

2604483 |

Main Shaft (output)

4WD (19-11/32")

32-37-31 Splines |

T170-2M

E1TZ-7061-C

2604466 |

Counter Shaft

0.891" diameter

10-1/8" long |

WT296-3

2602657 |

Counter Shaft Cylindrical Roller Bearings

42 required |

C4AZ-7121-A

Timken

QAR33724

BCA Federal Mogul

C1086Q |

| Reverse Idler Shaft |

WT296-35

2602658 |

Reverse Idler Cylindrical Roller Bearings

44 required |

C0DZ-7121-A

C407Q

BCA Federal Mogul |

Reverse Idler Gear

16T

25 Splines

3-17/32" long |

WT296-10A

T170-10B??

2602659

8132399 |

Reverse Idler Gear

16T

25 Splines

3-17/32" long |

T170-10B

2603617

8132399

D7DZ-7141-A |

Reverse Idler Sliding Gear

19 Spur Tooth

|

T170-10C

WT296-10C

2605066

8132402

D9BZ-7D223-A |

1-2 Synchro Sleeve

w/ Mainshaft Reverse Gear

22 Spur Tooth |

WT296-81

2605139 |

1-2 Synchro Hub & Sleeve Asm

(long keys) |

1AT170-80B

2670167 |

3-4 Synchro Hub & Slider Asm

(short keys) |

1AT170-2.5B |

| 1-2 Fork |

T170-23E |

| 3-4 Fork |

T170-23F |

| Reverse Fork |

T170-23G |

| RTS Shift Lever Steel Retaining Cap |

E4TZ-7220-A |

| Shift Lever Knob Insert (F-150 RTS) 1-2-3-OD-R |

E4TZ-7N280-A |

| Shift Lever Knob Insert (Ranger) 1-2-3-4-R |

E2TZ-7N280-A |

| Shift Lever Knob Insert (F-150 RUG) R-1-2-3-OD |

E2TZ-7N280-B |

| Shift Lever Knob Insert (F-150 T18, T19, NP435) 1-2-3-4--R |

E2TZ-7N280-D |

|

| Parts to Convert 'D Ratio' RTS Transmission into 'B Ratio' |

Part Numbers Needed |

Iron RUG 3+1 Cluster Gear

32-35-23-15T

Use w/ T170-11C, 18T Overdrive Gear (below)

from a 1978-87 Iron RUG-CB, CD, CL, FP, FZ, or GA

to convert an RTS 'D ratio' from 41.1% into a 'B ratio' 27.6% OD,

or for use as a replacement gear in an existing 27.6% RTS 'B ratio' |

T170-8C

D8UZ-7113-A

2603740 |

Iron RUG 3+1 4th Gear (OD)

18T

Use w/ T170-8C, 32-35-23-15 Cluster Gear (above)

from a 1978-87 Iron RUG-CB, CD, CL, FP, FZ, or GA

to convert an RTS 'D ratio' from 41.1% into a 'B ratio' 27.6% OD,

or for use as a replacement gear in an existing 27.6% RTS 'B ratio' |

T170-11C

D8UZ-7B340-A

2603737 |

|

| Parts to Convert any Ratio RTS Transmission into "Goldilocks" |

Part Numbers Needed |

Iron RUG 3+1 Cluster Gear

31-34-23-15T

Use w/ T170-11D, 19T Overdrive Gear (below)

from a 1978-79 Iron RUG 5.8L 351 V8 Econoline

to convert an any RTS ratio into a "Goldilocks" 27.0% OD |

T170-8D

D8UZ-7113-D

2603745 |

Iron RUG 3+1 4th Gear (OD)

19T

Use w/ T170-8D, 31-34-23-15 Cluster Gear (above)

from a 1978-79 Iron RUG 5.8L 351 V8 Econoline

to convert any RTS ratio into a "Goldilocks" 27.0% OD |

T170-11D

D8UZ-7B340-B

2603744 |

Iron RUG or Aluminum SROD/RTS Input Gear

22T

Use w/ T170-8D, 31-34-23-15 Cluster Gear (above)

and w/ T170-11D, 19T Overdrive Gear (above)

from a 1978-79 Iron RUG 5.8L 351 V8 Econoline

to convert any RTS 'B' or 'D' ratio into a "Goldilocks" 27.0% OD

(Reuse existing 22T Input Gear if converting a 'C' ratio RTS) |

1978-79

T170-16G

D8UZ-7017-B

2603806

or

1980-87

T170-16P

E0TZ-7017-C

2604485 |

|

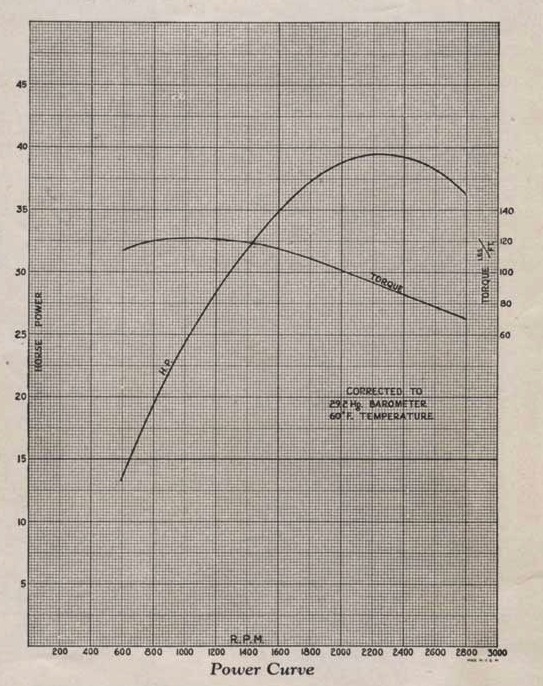

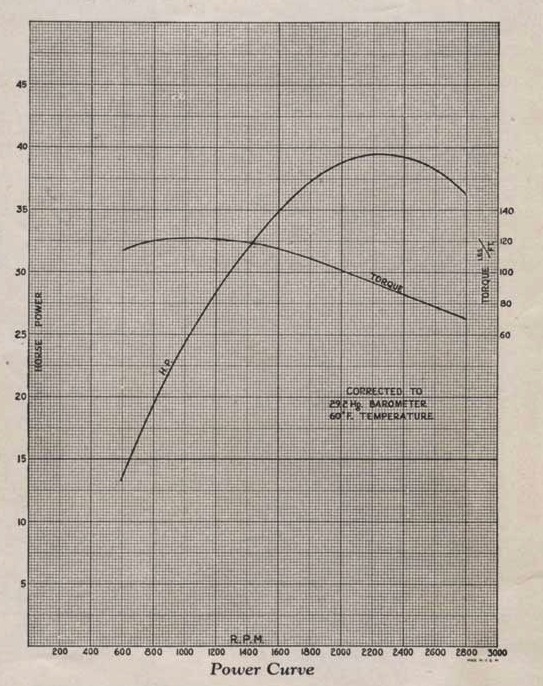

Drivability Considerations ~ Torque and Power

Overdrives are a Physics problem, not just a Mathematics problem!

Increased Torque and HP at the right RPM are required to go faster at lower engine RPM, not just mechanical overdrive gear ratios!

Any Model A or B Ford would benefit from the added engine torque and horsepower of a 5.5 or greater compression ratio cylinder head and a Stipe IB330 camshaft.

Essentially, top vehicle speed will occur when aerodynamic drag equals power output.

Proper gearing keeps the engine RPM in the useful range between "just below max torque" to “around max power” for all road speeds.

fordgarage.com

fordgarage.com

Improper gearing results in lugging the engine at low RPMs and destroying Babbitt engine bearings!

Lugging occurs when the engine is operated under load at below peak torque for any length of time.

Also, don't forget to improve your brakes!

Drivability and Suitability ~ Recommended Combinations

Highlighted below are the relative drivability improvements of various transmission gearings compared to the stock Model A gearing. Assumptions are based on stock tire sizes and engine configuration.

Assessments are based on general drivability and touring type usage. Not based on racing or any competitive performance usage.

Blue-shaded baseline attributes are equivalent to the stock Model A.

Green-shaded transmissions, ratios, and attributes are preferred for improved drivability compared to stock Model A.

Yellow-shaded attributes are questionable.

Violet/Red-shaded are the least desirable.

Three-Speed

Transmission |

Rev |

1st |

2nd |

3rd |

4th |

% OD |

Optimal Drivability and Suitability ~

Recommended Combinations and Usage Notes |

Stock Model A

1928-31 |

3.745:1 |

3.12:1 |

1.85:1 |

1:1 |

~ |

~ |

- 4.11 rear axle in a heavy-medium weight car and/or hill terrain.

- 3.78 rear axle in a medium-light weight car.

- 3.54 rear axle in a light weight car and/or flat terrain.

|

Stock Model B

1932-34 |

3.383:1 |

2.820:1 |

1.604:1 |

1:1 |

~ |

~ |

- 4.11 rear axle in a heavy-medium weight car and/or hill terrain.

- 3.78 rear axle in a medium-light weight car.

Synchronized 2nd and 3rd gears.

Taller 1st and 2nd gear ratios compared to Model A.

When coupled with a 27% Laycock, or 26% Mitchell driveshaft overdrive unit (or 36% OD unit with a 4.11:1 axle), this transmission would be an excellent solution for both low speed and high speed drivability, though without an internal transmission overdrive gear.

CON: Significant added unsprung OD mass on torque tube with Mitchell OD.

CON: Extra OD shift lever on floorboard with Mitchell OD. |

1931 Ruckstell

Dual High |

|

2.50:1 |

1.00:1 |

0.80:1 |

~ |

25% |

- 4.11 rear axle in a heavy-medium weight car and/or hill terrain.

- 3.78 rear axle in a medium-light weight car.

1st gear ratio is even taller than Model B.

2nd gear ratio is direct, 1:1

3rd gear ratio is a 25% overdrive, not 1:1.

1st to 2nd gear gap is actually worse than stock Model A.

Increased engine Torque and HP are highly recommended. |

Mitchell Synchro

15% 2nd only

Model A Trans |

|

3:12:1 |

1.61:1 |

1:1 |

~ |

~ |

- 4.11 rear axle in a heavy-medium weight car and/or hill terrain.

- 3.78 rear axle in a medium-light weight car.

- 3.54 rear axle in a light weight car and/or flat terrain.

Synchronized 2nd and 3rd gears.

15% Taller 2nd gear ratio is similar to Model B.

CON: Expense, but no improvement in 1st gear ratio. |

Mitchell Synchro

15% 1st & 2nd

Model A Trans

plus

Mitchell

Torque Tube

26% OD |

|

2.71:1 |

1.61:1 |

1:1 |

~ |

0.79:1

26% |

- 4.11 rear axle in a heavy-medium weight car and/or hill terrain.

- 3.78 rear axle in a medium-light weight car.

Synchronized 2nd and 3rd gears.

15% Taller 1st and 2nd gear ratios are similar to Model B.

When coupled with a 26% Mitchell driveshaft overdrive unit (or 36% Mitchell OD unit with a 4.11:1 axle), this Mitchell transmission approaches the "Goldilocks" 3+1 OD RTS transmission solution for both low speed and high speed drivability, though without an internal transmission overdrive gear.

CON: Significant added unsprung OD mass on torque tube with Mitchell OD.

CON: Extra OD shift lever on floorboard with Mitchell OD.

CON: Expense of both a Mitchell Transmission and a Mitchell OD. |

Mitchell Synchro

15% 1st & 2nd

Model A Trans

plus

Laycock J-Type

Torque Tube

27% OD |

|

2.71:1 |

1.61:1 |

1:1 |

~ |

0.79:1

27% |

- 4.11 rear axle in a heavy-medium weight car and/or hill terrain.

- 3.78 rear axle in a medium-light weight car.

Synchronized 2nd and 3rd gears.

15% Taller 1st and 2nd gear ratios are similar to Model B.

The 27% Laycock J-Type electro hydraulic planetary torque tube overdrive, combined with this Mitchell transmission, exceeds the "Goldilocks" 3+1 OD transmission solution for both low speed and high speed drivability.

PRO: Lightweight torque tube OD with electric shift switch.

PRO: One-for-one transmission, torque tube, and driveshaft swap. No other driveline modifications. No levers, no cutting or modifying radius rods, crossmembers, brakes, etc.

CON: Expense of both a Mitchell Transmission and a Laycock OD. |

|

3+1 Overdrive

Transmission |

Rev |

1st |

2nd |

3rd |

4th |

% OD |

Optimal Drivability and Suitability ~

Recommended Combinations and Usage Notes |

Stock Model A

1928-31 |

3.75:1 |

3.12:1 |

1.85:1 |

1:1 |

~ |

~ |

Model A BASELINE - Stock tire sizes and engine configuration.

Stock Model A 1st and 2nd gear ratios are actually quite poor.

Stock Model A 2nd to 3rd gear gap is actually quite large, and rear axle ratios and tires cannot improve this. |

Stock Model B

1932-34 |

3.38:1 |

2.820:1 |

1.604:1 |

1:1 |

~ |

~ |

Model B REFERENCE - Stock tire sizes and engine configuration.

Stock Model B 1st and 2nd gear ratios are improved over Model A.

Stock Model B 2nd to 3rd gear gap is improved over Model A. |

Goldilocks

Gearing

27.0%

T170F RUG 3+1

Goldilocks

gears in a

T170FT RTS case |

3.01:1 |

3.01:1 |

1.78:1 |

1:1 |

0.79:1 |

27.0% |

Well suited for Model A and Early V8 Ford.

(originally configured by Ford/TREMEC in a T170F iron RUG SMOD case for an Econoline van with the 5.8L 351 V8, not an F-150 T170FT RTS TOD case)

See the RUG SMOD Specification Table at top of page for the exact RUG 3+1 parts required to configure this transmission in an RTS case.

- 4.11 rear axle in a heavy-medium weight car and/or hill terrain.

- 3.78 rear axle in a heavy-medium-light weight car.

- 3.54 rear axle in a medium-light weight car and/or flat terrain.

- 3.27 rear axle in a light weight car and/or flat terrain.

Fully synchronized.

Taller 1st and 2nd gear ratios are more favorable compared to stock Model A.

Conversely, 1st and 2nd gear ratios are slightly less favorable compared to stock Model B.

Improved 2-3 shift gap compared to stock Model A.

4th gear (overdrive) ratio is more favorable for most Model A and early V8 era Fords compared to 'C ratio' and 'D ratio' transmissions.

Best suited for both city and highway driving, and across a range of axle ratios, weights, and terrain.

Increased engine Torque and HP are recommended. |

RTS 'C ratio'

37.9%

TREMEC

T170FT RTS

F-150 TOD |

3.01:1 |

3.01:1 |

1.78:1 |

1:1 |

0.72:1 |

37.9% |

Most often originally used in 4WD and 2WD Broncos (and F-150s) with the 5.8L 351 V8

Suited for Model A and Early V8 Ford.

- 4.11 rear axle in a heavy-medium weight car with added power (and/or flat terrain in OD).

- 3.78 rear axle in a medium-light weight car with added power and/or flat terrain.

- 3.54 rear axle in a light weight car and/or flat terrain.

Fully synchronized.

Taller 1st and 2nd gear ratios are more favorable compared to stock Model A.

Conversely, 1st and 2nd gear ratios are slightly less favorable compared to stock Model B.

Improved 2-3 shift gap compared to stock Model A.

4th gear (overdrive) ratio is less favorable for Fords with 3.78:1 axle ratios, but is good for 4.11 axle ratios especially in flathead V8 Fords, compared to RTS 'B ratio' transmissions.

Better suited for city driving and general driveability.

Increased engine Torque and HP are highly recommended for highway driving in OD (4th gear). |

RTS 'B ratio'

27.6%

TREMEC

T170FT RTS

F-150 TOD |

3.25:1 |

3.25:1 |

1.92:1 |

1:1 |

0.78:1 |

27.6% |

Most often originally used in 5.0L 302 V8 F-150s

Despite being demonstrably somewhat 'worse' than a stock Model A for low speed and city drivability, the 'B ratio' is the most popular and commonly converted RTS, and is well accepted by many Model A owners with a 3.78:1 axle ratio.

- 4.11 rear axle in a heavy-medium weight car and/or hill terrain.

- 3.78 rear axle in a heavy-medium-light weight car.

- 3.54 rear axle in a medium-light weight car and/or flat terrain.

- 3.27 rear axle in a light weight car and/or flat terrain.

Fully synchronized.

1st and 2nd gear ratios are somewhat 'worse' than stock Model A, and considerably worse than a stock Model B.

2nd to 3rd gear gap is somewhat 'worse' than stock Model A, and considerably worse than a stock Model B.

4th gear (overdrive) ratio is more favorable for most Model A and early V8 era Fords compared to 'C ratio' and 'D ratio' transmissions.

Better suited for highway driving and/or underpowered engines.

Increased engine Torque and HP are recommended. |

RTS 'D ratio'

41.1%

TREMEC

T170FT RTS

F-150 TOD

Recommend

converting to

27.6% 'B ratio'

by changing

the internal Cluster Gear

and the 4th

(OD) Gear. |

3.25:1 |

3.25:1 |

1.92:1 |

1:1 |

0.71:1 |

41.1% |

Most often originally used in 4.9L 300 I6 F-150s

Not Recommended - no benefits for most Model A and early V8 driving cars!

Basically a gear set designed for a straight six (high flat torque curve) work

truck having a slow rear axle, but with an added highway OD gear to achieve

higher advertised fuel economy ratings.

- 4.11 rear axle in a medium weight car with added power and/or flat terrain.

Bad 1-2 gear ratios, bad 2-3 shift gap. - 3.78 rear axle in a light weight car and/or flat terrain.

Poor 1-2 gear ratios, bad 2-3 shift gap, steep 4th gear ratio. - 3.54 rear axle in a light weight car and/or flat terrain.

Bad 2-3 shift gap, bad 4th gear ratio. - 3.27 rear axle in a light weight car and/or flat terrain.

Bad 2-3 shift gap, bad 4th gear ratio.

Fully synchronized.

1st and 2nd gear ratios are somewhat 'worse' than stock Model A, and considerably worse than a stock Model B.

2nd to 3rd gear gap is somewhat 'worse' than stock Model A, and considerably worse than a stock Model B.

4th gear (overdrive) ratio is very unfavorable for Model A and early V8 era Fords compared to 'B ratio' and 'C ratio' transmissions.

Increased engine Torque and HP are required for highway driving in OD (4th gear). |

|

Rev |

1st |

2nd |

3rd |

4th |

% OD |

|

Blue-shaded baseline attributes are equivalent to the stock Model A.

Green-shaded transmissions, ratios, and attributes are preferred for improved drivability compared to stock Model A.

Yellow-shaded attributes are questionable.

Violet/Red-shaded are the least desirable.

Conversion and Installation Considerations

It is only recommended to use the Model AA truck four-speed transmission clutch (bell) housing as the basis for the conversion, rather than the Model A three-speed transmission clutch housing.

fordgarage.com

fordgarage.com

The 1929-31 Model AA truck clutch housing is nearly 2" shorter fore-aft compared to a Model A three-speed housing, and its use requires no modification to the frame center crossmember for clearance to the transmission and U-Joint covers.

Both the Model AA and BB truck clutch housings have the same critical dimensions.

The inside diameter of the opening for the transmission front drive gear retainer is 4-3/4 inches (4.750").

The fore-aft dimension between the flywheel housing contact surface and the transmission case mounting surface is 5-9/16 inches (5.5625"). By comparison, a Model A clutch housing is longer at 7-5/8 inches.

The Model BB clutch housing does not have any front radius rod (wishbone) mounting provisions compared to a Model AA housing, but the BB housing is necessary when using a Model B/BB flywheel housing and uncut Model B oil pan. Model AA and BB flywheel housings and clutch housings are not interchangeable with each other. They must also be paired along with the corresponding A or B oil pan.

Use of either the Model AA or BB clutch housing does however require fabrication of brake and clutch pedal mounting provisions. A provision for mounting the emergency brake handle to the transmission must also be fabricated.

The shift lever opening position in the floorboard and mat is slightly affected, moving rearward about 1-5/8 inches from the stock Model A position.

The Model AA throwout bearing hub, AA clutch release shaft, both AA clutch arms, and Model A pressure plate are used with a 1949-57 Ford clutch disc B7A-7550-D.

A C5NN-7600 pilot bearing and C0NN-7580-A throwout bearing can also be used.

Alternatively, a 8-7/8 inch diaphragm pressure plate and matching clutch driven disc for a 1983-88 Ford four cylinder 2.3L Thunderbird or 1984-86 Mustang SVO 2.3L turbo can be mounted to a lightened and faced Model A or B flywheel by drilling and tapping six additional holes. The 2.3L turbo's 8-7/8 inch clutch disc hub has the same 1-1/16 inch x 10 spline as the TREMEC RTS input shaft.

The system conversion based on the Model AA clutch housing also requires the shortening of the Model A torque tube, drive shaft, and rear radius rods according to the specific rear main bearing retainer design used for conversion.

To provide clearance to the center crossmember flange, cut off the top center bolt hole tabs on the inner and outer Model A universal joint upper clamshells, or alternatively, use the early V8 era four-bolt clamshells. Design the hole pattern in the rear main bearing retainer for the chosen clamshell design.

Additionally, a suitable rear transmission support must be fabricated. Some builders hang the transmission off the top of the center frame crossmember using the new rear bearing retainer. I prefer a separate added fabricated crossmember with rubber trans mount supporting the bottom of the new rear bearing retainer.

Modification to the TREMEC transmission itself involves:

-

Drilling and tapping the front of the RTS case 6 places for the Model AA clutch housing attaching bolt locations.

-

Reduction of the RTS front main bearing retainer outside diameter size to fit the Model AA clutch housing 4.750 inch bore. (for reference, the stock TREMEC retainer outside diameter is 4.850 inches)

-

Enlargement/sleeving of the RTS front main bearing retainer diameter to match the Model AA throwout bearing hub. This can be accomplished by cutting off the front snout of a Model A or Early V8 retainer, and brazing or JB Weld'ing it onto the RTS snout. The complementary IDs and ODs make this the easiest approach when maintaining the stock Model AA throwout bearing hub.

-

Fabrication of a throwout bearing return spring attaching bracket using the two upper bolts of the front main bearing retainer. A simple strap bracket spanning both bolts, with a turned flange with hole at the center will work.

-

Shortening of the RTS (main drive gear) input shaft pilot nose length by about 5/8 inches, and removal of about 1/4 inch of spline length from the front of the input shaft.

-

Replacement of the RTS tail shaft extension with a suitable rear bearing retainer adaptor plate.

(for reference, the stock Model A rear bearing retainer thickness is 1-5/16 inches (1.3125") between the gasket mounting surfaces.)

-

Shortening, splining, drilling and tapping of the rear of the RTS transmission output (main) shaft for mounting the Model A universal joint. A 4WD RTS shaft is better than a 2WD shaft as a starting point, and provides more 'meat' at the U-joint spline location, but either RTS shaft can work.

-

Adaptation of the RTS shift lever to suit the user's needs. A 1980-86 Jeep T176 one-piece cane shift lever can be adapted to replace the Ford F-150 RTS stub shifter shaft. Search for Crown Automotive 5359835 shift lever.

Disassemby and Reassembly Tools

Important:

The RTS transmission gears and shift tower lever position must be in second gear when removing (and re-installing) the shift tower to the case.

Remove the six tower attaching screws and then use the four pry bar tabs on the shifter tower/cover casting for leverage in order to break the bond of the anaerobic gasket sealer to the case. That's what the tabs are there for!

The shift tower rolls out slightly towards the right side during removal, rather than lifting straight up from the case. Opposite for reassembly.

Additionally and importantly, when re-installing the shift tower to the case, the reverse idler sliding gear must be positioned fully towards the rear, and the transmission gears and shift tower must be in the second gear position, and all three forks must be aligned with their respective grooves in gears, sleeves, and hubs.

Failure to position the reverse idler sliding gear to the rear for reassembly will cause the reverse fork to be out of engagement (behind its groove in the sliding gear). Reverse cannot be engaged in that condition, though 1st through 4th will still shift.

Cleanliness Note: If you are doing these tasks in any complete vehicle with an upholstered interior, it may be wise to first remove the lever from the tower. Unscrew the large threaded steel cap at the lever pivot and remove the lever with the transmission in second gear. Then proceed as described above for shift tower removal and installation to the case.

Because of the unique internal design, construction, and gear diameters of the RUG 3+1 and RTS overdrives, neither the input nor output shaft can readily be removed from the case without first pulling the press-fit ball bearings from the case and shafts, as well as pulling the countershaft. The opposite sequence is necessary for reassembly. Special Ford Rotunda service tools were developed in order to accomplish this without damage while the trans is on the bench.

Even after removing the bearings, there are a number of steps in particular sequence necessary to get the entire transmission apart and the case emptied (see Service Manual download link at top of page). It is not as easy or straightforward as working on a conventional Ford four-speed performance toploader of the 1960s-70s.

| Ford Rotunda/OTC ~ Essential Service Tools for Manual Transmissions |

| Rotunda Number |

OTC Number |

Bolded/Green-Shaded tool numbers are very useful for RTS 3+1 OD |

|

| T57L-500-B |

|

Bench Mounted Holding Fixture |

|

| T63P-7111-A |

|

Dummy Countershaft Tool

(0.865 OD x 5.570 long)

(RAT/RAN)? |

|

| T63P-7111-B |

|

Dummy Countershaft Tool

(0.865 OD x 5.070 long)

(RAT/RAN)? |

|

| T64P-7111-A |

308-003 |

Dummy Countershaft Tool

(0.880 OD x 8.865 long)

(RUG, RUG 3+1, RTS) |

|

| T71P-7111-A |

|

Dummy Countershaft Tool

(0.680 OD x 7.143 long) |

|

| T74P-7111-B |

|

Dummy Countershaft Tool

(~0.740 OD x ~7.500 long) |

|

| T83T-7111-B |

308-088 |

Dummy Countershaft Tool

(~1.115 OD x ~9.750 long) |

|

|

|

Dummy Countershaft Tool

(0.740 OD x ~5.000 long)

(Model A) |

|

|

|

Dummy Countershaft Tool

(0.740 OD x ~6.625 long)

(EV8 car) |

|

| T64P-7140-A |

|

Dummy Reverse Idler Shaft Tool

(0.740 OD x 3.805 long)

(RAB, RAN, RUG, RUG-BP, RUG 3+1) |

|

|

| T75L-7025-A |

|

Transmission Bearing Service Set |

|

| T75L-7025-B |

308-024 |

Remover/Replacer Tube (Short)

(RTS Input Shaft Bearing Remove/Install) |

|

| T75L-7025-C |

308-025 |

Remover/Replacer Tube (Long)

(RTS Output Shaft Bearing Remove/Install) |

|

| T75L-7025-D |

308-027 |

Bearing Collet (2), Car-Large

(HEH, RUG, RUG-BP Output, 35/80/21mm 307 size bearing) |

|

| T75L-7025-E |

308-027 |

Bearing Collet (2), Car-Small

(Output, 35/72/17mm 207 size bearing) |

|

| T75L-7025-F |

308-028 |

Bearing Collet (2), Truck

(RUG 3+1, RTS, SROD, 40/90/23mm 308 size bearing) |

|

| T75L-7025-G |

308-029 |

Bearing Collet Sleeve (Car) (207/307 size bearing)

(HEH, RUG, RUG-BP Output) |

|

| T75L-7025-H |

308-030 |

Bearing Collet Sleeve (Truck) (209/308 size bearing)

(RUG 3+1, RTS, SROD) |

|

| T75L-7025-J |

see 308-092 |

Forcing Screw (15/16-12 x 8-3/8" long)

(RUG 3+1, RTS Input Shaft Remove; 2WD Output Shaft Remove) |

|

| T75L-7025-K |

308-031 |

Bearing Shaft Collar Installer

(RTS Input/Output Shaft Bearing Install) |

|

| T75L-7025-L |

308-032 |

Threaded Shaft Adaptor

(Internal/External Threaded) (for RTS w/ Model A U-Joint Splines) |

|

| T75L-7025-M |

308-033 |

Bearing Shaft Collar Installer

(0.960" ID Ranger M5OD-R1) |

|

| T75L-7025-N |

308-034 |

Bearing Shaft Collar Installer

(0.812" ID Ranger RAD) |

|

| T75L-7025-P |

308-035 |

Bearing Shaft Collar Installer

(1.065" ID RTS 2WD Output Shaft Bearing Install; Ranger M5OD) |

|

| T75L-7025-Q |

308-036 |

Replacer Dummy Bearing

(Borg Warner T-18, T-19; 35/40mm ID, 72/90mm OD) |

|

| T75L-7025-R |

308-037 |

Bearing Shaft Collar Installer

(Borg Warner T-18, T-19) |

|

| T75L-7025-S |

308-038 |

Bearing Shaft Collar Installer

(Borg Warner T-18, T-19) |

|

|

| T77F-7025-A |

|

Bearing Collet (2), (2.677 OD)

(40/68/15mm 6008 size bearing) |

|

| T77F-7025-B |

|

Bearing Collet (2), (2.440 OD)

(25/62/17mm 305 size bearing) |

|

| T77F-7025-C |

308-049 |

Bearing Collet Sleeve |

|

| T77F-7050-A |

|

Seal Installer (Input Bearing Retainer) |

|

| T77F-7050-B |

|

Seal Remover (Input Bearing Retainer) |

|

|

| T77L-7025-F |

|

Transmission Bearing Service Set (RUG-BP) |

|

| T77L-7025-A |

308-065 |

Bearing Collet (2), (3.3465 OD)

(HEH, RUG, RUG-BP Input, 45/85/19mm 209 size bearing) |

|

| T77L-7025-B |

308-066 |

Dummy Bearing

(HEH, RUG, RUG-BP Output 35/80/21mm 307 size bearing) |

|

| T77L-7025-C |

308-067 |

Remover/Replacer Tube (Short)

(RUG 3+1, RTS, SROD Input Shaft Bearing Install) |

|

| T77L-7025-D |

308-068 |

Shaft Clamp

(RUG 3+1, RTS, SROD Input Shaft Bearing Install) |

|

|

| T84T-7025-A |

308-091 |

Bearing Replacer

(RTS 4WD Output Shaft Bearing Install) |

|

| T84T-7025-B |

308-092 |

Forcing Screw (15/16"-12 x 11.5")

(RTS 4WD Output Shaft Bearing Remove) |

|

|

| Fabricate |

|

Bearing Installer ~ Double-Stud Adaptor

(for modified RTS Output Shaft with Model A U-Joint Splines)

(use with T75L-7025-L and T75L-7025-B ) |

|

| Fabricate |

|

Alternate Bearing Installer ~ Heavy Bushing

(for modified RTS Output Shaft with Model A U-Joint Splines)

(use with T75L-7025-K, T75L-7025-R, T75L-7025-B, and hex bolt ) |

|

| Fabricate |

|

Bearing Remover ~ Button-Head Centering Stud

(for modified RTS Output Shaft with Model A U-Joint Splines)

(use with T75L-7025-F, T75L-7025-B, and T84T-7025-B) |

|

| Fabricate |

|

Alternate Bearing Remover ~ Hex Bolt Centering Stud

(for modified RTS Output Shaft with Model A U-Joint Splines)

(use with T75L-7025-F, T75L-7025-B, and T84T-7025-B) |

|

| Fabricate |

|

F-150 Shift Lever Removal Tool ~ Plastic Lock Pins Depressor C Clamp

(for removing RTS lever tube from the lower forged shift lever) |

|

| Procure |

|

Pry Bar, Pin Punch, Hammer, Snap Ring Pliers, 1/2" & 5/8" Tools,

Chain Wrench for Shift Lever Retaining Cap |

|

More related information on Ford Garage:

- For more Model A & B related information, use the Site Search box at the top or bottom of this page.

- Model A Ruckstell Dual High Transmission

- Model A Mitchell Synchronized Transmission

- Model A & B Rear Axle Gear Ratios

- Model AA Four-Speed Transmission Clutch Housing

- Model A & B Drive Shaft Differences

Vince Falter

December 2017

fordgarage.com

fordgarage.com