Model A & B

Ford Garage

Camshaft Timing Gears

There have been a variety of engine camshaft gear designs and materials used over the years for the Model A and B. Shown below are a series of pics showing some of the variations.

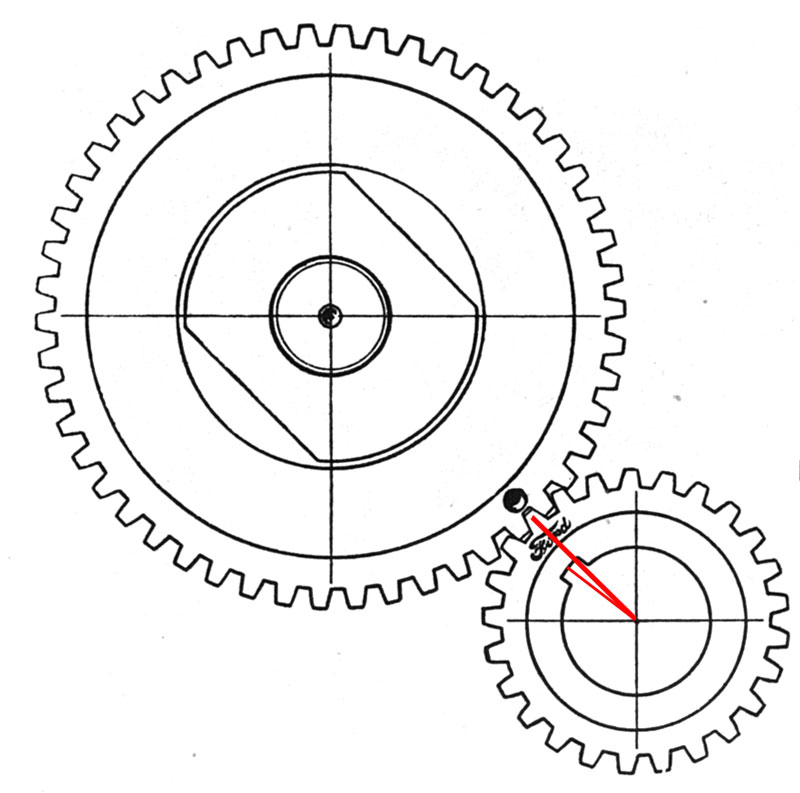

The camshaft gear has 50 helical cut teeth, and rotates at half the engine speed. The crankshaft gear has 25 helical cut teeth and rotates at engine speed.

fordgarage.com

fordgarage.comThe original Ford engine camshaft gear was a phenolic construction made up of laminations of fabric. These are often found with Ford script and the logos or identification of manufacturing companies such as Formica, Celoron, Micarta, and others. The main feature of these gears is quiet running when used with a good crankshaft gear.

These genuine Ford gears were produced both with and without the aluminum hub center shown above.

In the extreme case, the fabric gear can separate from the metal hub, though the teeth usually fail first.

fordgarage.com

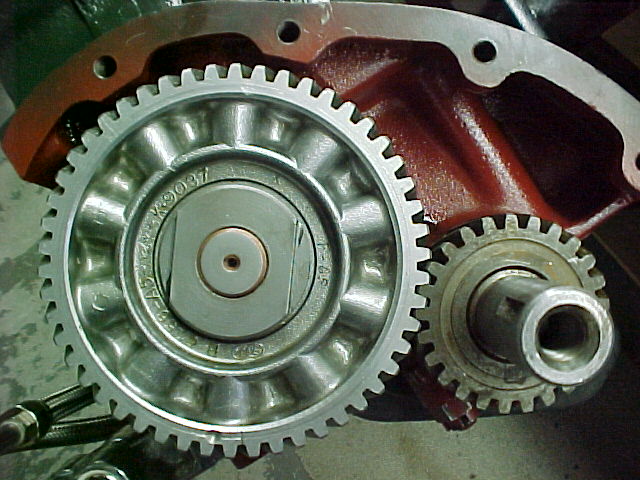

fordgarage.comPictured above is a replacement cast iron crankshaft gear. The original crankshaft gears were similarly made of cast iron and worked well if not corroded. When corroded, any crankshaft gear will have the tendency to prematurely wear out the camshaft gear.

The direction of the helix of the gears causes the driving gear (crankshaft) to force the driven gear (camshaft) rearward against the camshaft thrust surface of the block.

The spring plunger in the gear cover at the front of the camshaft responds to oscillations in the contact forces between the helical teeth, and is not carrying any thrust load related to the valve springs.

In later years it became popular to use machined cast and billet aluminum camshaft timing gears because they were deemed more robust than the fabric gears. The metal camshaft gears are also credited with being noisier than original fabric gears.

fordgarage.com

fordgarage.comShown above is an Alcoa aluminum camshaft gear. Below is a no-brand aluminum gear from the 1970s.

fordgarage.com

fordgarage.com

fordgarage.com

fordgarage.comShown above is an original Ford machined die-cast aluminum camshaft gear which was used in the German G28T engines. This style of gear was also produced in Canada at some point.

fordgarage.com

fordgarage.comFor the ultimate gear-head, Bill Stipe produced this steel hub and billet aluminum camshaft gear, shown above. It is adjustable in order to vary the cam and valve timing relative to crankshaft and piston position. The two-piece gear has a built-in vernier to dial in the exact angle changes desired.

This two-piece gear has a lot of potential use as a development tool to determine a custom cam gear timing for use in a particular engine configuration, and could be used to specify a custom clocking on a one-piece gear.

If it were to be used in continuous harsh use, there are a couple details worth considering. First, there are only six screws retaining the aluminum gear to the steel hub, and there is minimal clamp load footprint of the washers to the slots in the aluminum gear.

Secondly, there is no hard stop controlling the angular position of the gear to the hub, or to transfer any rotational load between them. There is only the clamping force of the aforementioned six screws and washers on the slots. If the gear loses screw clamp to the hub and slips, it will impact the cam timing and possibly the gear mesh.

fordgarage.com

fordgarage.com

There have also been a couple of sources of machined bronze gears in past years.

Shown above is a billet bronze gear once made by Ron Kelley.

In addition, Dan McEachern makes both machined cast bronze and cast aluminum camshaft timing gears, as well as steel crankshaft gears.

fordgarage.com

fordgarage.comPictured above and below is the currently available Dan McEachern machined cast bronze camshaft timing gear, as well as his steel crankshaft gear.

fordgarage.com

fordgarage.com

For top quality matched metal gears, contact:

Dan McEachern

920 Pearl St

Alameda, California 94501

(510) 532-8228 work

(510) 769-7524 cell

dmcgears@yahoo.com

fordgarage.com

fordgarage.comShown above and below is an example of a vintage steel camshaft gear which came out of a Riley racing engine.

fordgarage.com

fordgarage.comShown below is an example of another iron/steel camshaft gear. This NOS gear was made by Gleaner for Model A engine powered Baldwin combines for driving the side timing cover mounted Pierce engine governor.

It is similar in appearance to a Model T cam gear, but in Model A dimensions and tooth count.

fordgarage.com

fordgarage.com

fordgarage.com

fordgarage.com

fordgarage.com

fordgarage.comThe restoration market has also been fraught with poor quality, inexpensive macerated fiber gears for many years. The macerated fiber style gears do not have any fabric construction, only short fibers.

Though available in all the restoration parts catalogs, they are the worst choice for a gear due to their lack of strength and their propensity to separate into fiber fluff and plug the oil pump and main bearing oil feed tubes.

The internet message boards and club magazines include numerous reports and photos of self destructive failures of macerated gears.

fordgarage.com

fordgarage.comThe final pic above shows the best replacement fabric reinforced phenolic timing gear currently available. This is a good quality gear. It is made from resinated laminations of textile fabric, similar to the originals.

This is a quality USA made fabric gear. This is not the macerated fiber gear sold by many suppliers.

fordgarage.com

fordgarage.comCheck out this great YouTube video from Ray White showing how to replace the gear!

More related information on Ford Garage:

- For more Model A & B related information, use the Site Search box at the top or bottom of this page.

- Model A & B Camshaft to Crankshaft Gear Alignment

- Model A & B Camshaft to Crankshaft Positioning

- Model A & B Engine Cam/Valve and Ignition/Spark Timing Discussion

- Model A & B Camshaft Gear Front Timing Cover Differences

- Model A & B Original 5-Z-1832 Cam Gear Wrench

- Model A & B Camshaft Thrust Plungers

- Model A & B Original Ford Camshaft Details

Vince Falter

January 2008